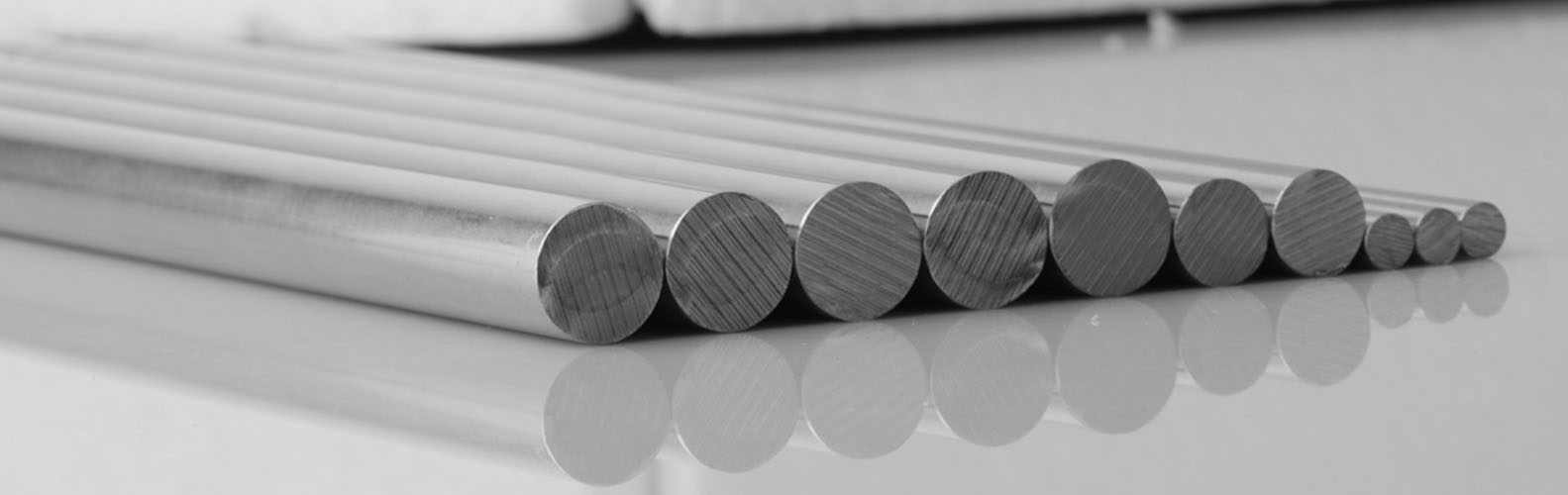

What is Stainless Steel 416PSQ Round Bar?

Stainless Steel 416PSQ Round Bar is one of the stainless steel bars for specific application in mechanical purposes. The description below explains the major elements of the material:

Stainless Steel: A corrosion-resistant alloy with a main composition of iron, chromium, and other elements. It is widely applied since it is rust-resistant, staining-resistant, and corrosion-resistant.

The martensitic stainless steel grade 416PSQ (Precision Square) Round Bar specifically provides applications with combined high strength and good corrosion resistance requirements. The grade designation “416” describes stainless steel materials with iron as its base element while chromium comprises 12 to 14 percent and minor quantities of carbon manganese and sulfur.

The final part of the name “PSQ” represents “Precision Square” indicating that this round bar achieves strict manufacturing standards for both dimensions and surface characteristics. The steel grade 416 can perform exact tasks related to machining and manufacturing processes where precision is essential.

Applications Stainless Steel 416PSQ Round Bar

Stainless Steel 416PSQ Round Bar maintains outstanding machining characteristics along with high strength properties besides moderate resistance to corrosive elements for different industrial uses. The PSQ designation indicates precise bar manufacturing capabilities which ensures the material works optimally for precise machining operations.

Aerospace and Aviation:

The machining characteristics and durability of 416 stainless steel lead to its use when producing aircraft components which include shafts aircraft valves and aircraft fasteners. The material offers resistance to damage and can tolerate various mechanical loads which occur in aviation applications.

Machinery and Manufacturing:

The material strength together with excellent wear properties of 416 stainless steel enables its application in pump shafts as well as valve stems and impellers for machinery. The industrial pumping system’s operational stresses do not damage this material.

Oil and Gas Industry:

The oil and gas sector makes extensive use of 416 stainless steel for valve components mainly due to its satisfactory combination of corrosion resistance and wear resistance properties by employing the material in valve stems and spindles and seats. The oil and gas industry benefits from using this material because it functions well even under abrasive applications that require precise machining.

Benefits of Stainless Steel 416PSQ Round Bar

Excellent Machinability:

The excellent machinability represents one main strength of 416 stainless steel. Sulfur in its chemical makeup enhances the material’s processing characteristics which enables effortless manufacturing of specific parts and components. The composition of 416PSQ round bars provides excellent results for manufacturing applications that need strict dimensional requirements and complex fabrication tasks. Production processing of 416PSQ round bars requires less time and costs less than most stainless steel grades mainly because of its superior workability.

Precision and Dimensional Accuracy:

Precision Square designation “PSQ” indicates that the round bar receives production with strict specifications and a refined surface quality. Components requiring strict precision benefit significantly from this high dimensional accuracy level because they belong to applications such as aerospace, automotive and medical fields. Round bars made from 416PSQ material deliver such precise dimensions that assembled components require minimum or no extra machining processes.

Magnetic Properties:

Stainless Steel 416 shows magnetic traits which constitute a characteristic missing from 304 or 316 stainless steel grades. Stainless Steel 416 provides desirable magnetic capabilities for use in electric motor design alongside generators and other mechanical equipment that needs to exhibit magnetic traits. The magnetic characteristic makes 416PSQ round bar suitable for producing rotors and shafts as well as magnetic components.

Properties of Stainless Steel 416PSQ Round Bar

Stainless Steel 416 shows magnetic traits which constitute a characteristic missing from 304 or 316 stainless steel grades. Stainless Steel 416 provides desirable magnetic capabilities for use in electric motor design alongside generators and other mechanical equipment that needs to exhibit magnetic traits. The magnetic characteristic makes 416PSQ round bar suitable for producing rotors and shafts as well as magnetic components.

Chemical composition of Stainless Steel 416PSQ Round Bar

| Grade | C | Ni | Si | S | Cr | Mn | Mn | P | Fe |

|---|---|---|---|---|---|---|---|---|---|

| SS 416 | 0.15 max | – | 1.0 max | 0.15 min | 14.00 – 12.00 | 1.25 max | 0.6 | 0.06 max | – |

High Strength and Hardness:

Heat treatment of Stainless Steel 416 produces parts with high tensile strength and hardness allowing their use in mechanical applications requiring resistance to stresses along with impact and wear conditions. Injection annealing allows the material to acquire similar strength levels to high-strength alloys without losing its workable properties.

Ultimate Tensile Strength: Around 85,000 psi (586 MPa).

The material achieves highest yield strength levels of 30,000 psi (207 MPa) through heat treatment.

The heat treatment methods determine the Rockwell hardness measurement range between C30 and C40 for this material.

Dimensional Accuracy and Precision

PSQ marking indicates that round bars possess both exact dimensions along with refined surfaces which enables containers to sustain precise tolerances without further finishing steps. The PSQ designation guarantees high dimensions accuracy which enables applications to require tight component fitting and alignment in aerospace, automotive as well as medical industries.

The production time shortens while costs diminish because post-machining adjustments become minimal which leads to high-quality precision-engineered parts.

Conclusion

The mechanical properties which characterize Stainless Steel 416PSQ Round Bar consist of superior machining characteristics and strong material properties and resistance to wear and moderate protection against corrosion. The PSQ designation guarantees that the material provides high precision which enables its use for applications needing precise tolerances and smooth finishes. Its low cost and magnetic character suits this product for multiple sectors including automotive and aerospace industries.